🚢 Mastering Cargo Operations: Principles of Safe Loading & Storage for Seafarers

- kousik pattanayak

- Jun 29, 2025

- 7 min read

Updated: Aug 4, 2025

⚓ Introduction: The Art and Science of Cargo Operations at Sea

In the dynamic world of maritime trade, the journey of goods from manufacturer to consumer hinges on one critical phase: cargo handling and storage. For every seafarer, from the newest cadet to the most experienced Master, a profound understanding of the principles of safe loading and unloading is not just a professional requirement – it's the bedrock of vessel integrity, cargo preservation, and, most importantly, the safety of life at sea.

This comprehensive guide is meticulously crafted for the seafarer community, aiming to demystify the complex yet vital aspects of cargo operations. We'll delve into the best practices that ensure your ship sails stably, your cargo remains intact, and your crew operates with utmost confidence.

📦 Decoding Cargo Handling in Shipping: More Than Just Moving Goods

At its core, cargo handling encompasses every action involved in transferring goods from shore to ship, positioning them correctly onboard, securing them for transit, and finally, transferring them back to shore. This intricate process includes:

Loading: The systematic process of bringing cargo onto the vessel.

Stowage: The art of efficiently arranging cargo within the ship's holds or on deck.

Securing (Lashing): The critical task of preventing cargo movement during the voyage.

Monitoring: Continuous observation of cargo condition (e.g., temperature, humidity) and stability.

Unloading: The reverse process of safely discharging cargo at the destination.

Documentation & Compliance: Ensuring all procedures adhere to international regulations and ship-specific manuals.

Every step requires precision, planning, and adherence to rigorous maritime cargo safety standards.

🧰 Understanding Diverse Cargo: Tailored Handling, Maximum Safety

Ships transport an astonishing variety of goods, each presenting unique cargo handling challenges. Recognizing these differences is key to effective cargo storage principles:

Cargo Type | Key Handling Considerations | Visuals for Blog |

Bulk Cargo (Grain, Coal, Ores) | Requires even trimming to prevent shifting (especially with liquefaction risks), careful monitoring of moisture content. |  |

Containerized Cargo | Stacked meticulously; secured with specialized fittings like twist locks, lashing rods, and bridge fittings. |  |

Liquid Cargo (Oil, Chemicals, LNG) | Handled via pipelines; necessitates precise tank calibration, inerting (for flammable liquids), and temperature/pressure control. |  |

General Cargo (Packaged Goods, Machinery) | Requires careful dunnage, chocking, and lashing with chains, wires, or specialized nets. |  |

Refrigerated Cargo (Reefer) | Demands continuous temperature monitoring and ventilation; specialized reefer containers or reefer holds. |  |

Heavy Lift/Project Cargo | Often requires specialized cranes (ship's gear or shore-based), extensive planning, and bespoke securing arrangements. |  |

Hazardous Goods | Strict adherence to IMDG Code (International Maritime Dangerous Goods Code) for segregation, labeling, and emergency response. |  |

🏗️ The Core Pillars: Principles of Safe Loading Procedures

Loading a ship is akin to a delicate balancing act. It's not just about capacity; it's about dynamic stability. Adhering to these principles is paramount for ship stability during loading:

Weight Distribution (Homogeneous Loading):

Cargo must be distributed as evenly as possible across all holds and decks. Avoid concentrating heavy weights in a single area, which can lead to excessive stress or shear forces.

Goal: Prevent dangerous listing (sideways tilt) or excessive trim (fore-and-aft tilt).

Maintaining Optimal Center of Gravity (GM - Metacentric Height):

Heavy cargo should always be stowed as low and as close to the vessel's centerline as possible.

Stacking heavy items on top of lighter ones raises the vessel's center of gravity, decreasing its metacentric height (GM) and making it less stable, particularly in rough seas.

Crucial Tool: The ship’s stability booklet and loading manual provide critical parameters and calculations for safe GM.

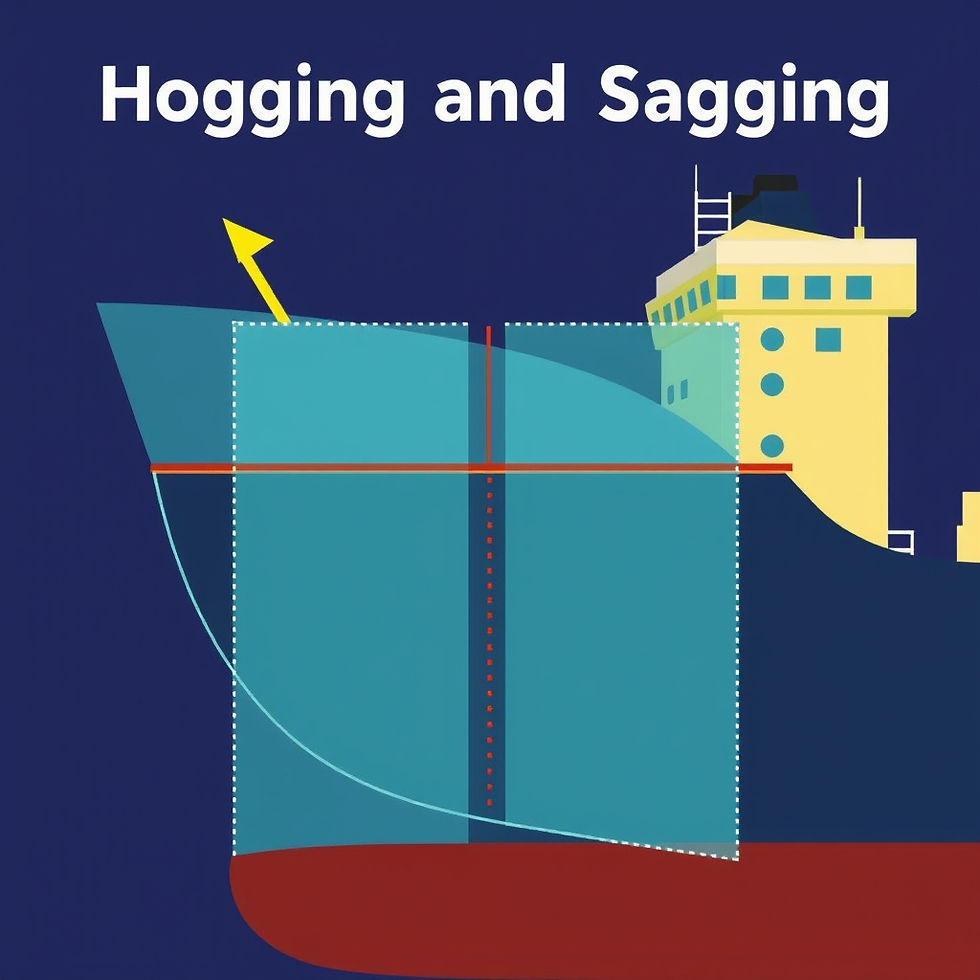

Managing Shear Forces and Bending Moments:

These are internal stresses on the ship's hull. Loading too much weight in the middle (hogging) or at the ends (sagging) can exceed structural limits.

Modern vessels use sophisticated loading software that calculates these stresses in real-time, allowing the cargo officer to adjust the plan.

Always: Operate within the vessel’s permissible shear force and bending moment limits specified in the loading manual.

⚠️ The Inverse Art: Principles of Efficient Unloading Practices

Unloading is not simply reversing the loading process. It demands equal, if not greater, vigilance, as changes in weight can rapidly alter a ship's stability.

Best Practices for Unloading:

Symmetrical Discharge: Aim to unload cargo symmetrically from both port and starboard sides to prevent severe listing.

Ballast Management: Continuously monitor and adjust ballast tanks to compensate for the reduction in cargo weight, maintaining an acceptable trim and list throughout the operation. This is vital for vessel stability.

Clear Communication: Maintain continuous and clear communication with stevedores and terminal operators. The ship's crew (especially the cargo officer) is ultimately responsible for the vessel's safety.

Sequence Adherence: Strictly follow the agreed-upon discharge plan, especially for bulk carriers to prevent structural overstress.

🛡️ The Unsung Hero: Cargo Securing Methods

Unsecured cargo is arguably the biggest preventable hazard at sea. A shifting cargo can lead to structural damage, capsizing, and loss of life. Effective cargo securing methods are non-negotiable.

Common & Effective Securing Techniques:

Lashing Rods & Turnbuckles: Standard for securing containers on deck.

Chains & Tensioners: Used for heavy machinery, vehicles, and break-bulk cargo.

Webbing Straps: Versatile for lighter, general cargo.

Dunnage: Wood, timber, inflatable airbags, or foam used to fill voids, prevent movement, and absorb shock.

Chocking: Wooden or metal blocks used to prevent rolling or sliding of wheeled cargo or circular items.

Twist Locks & Cones: Essential fittings for securing containers in stacks.

Anti-Skid Materials: Used under cargo to increase friction.

Pro Tip for Seafarers:

Regularly inspect all lashings and securing gear before departure and, crucially, during the voyage, especially after encountering heavy weather. Fatigue can loosen gear, and vigilance prevents disaster.

🧯 The Critical Zone: Handling Dangerous Goods & IMDG Code Compliance

When your vessel carries hazardous cargo, the IMDG Code (International Maritime Dangerous Goods Code) becomes your bible. Strict adherence is mandatory:

Proper Labeling & Documentation: Ensure every dangerous goods package is correctly labeled and accompanied by accurate documentation (Dangerous Goods Declaration, MSDS).

Segregation: Incompatible substances must be segregated according to the IMDG Code's tables to prevent dangerous reactions.

Emergency Preparedness: The ship must be equipped with appropriate fire-fighting apparatus, spill response kits, and crew trained in specific emergency procedures for each class of dangerous goods.

Ventilation: Proper ventilation is vital, especially for certain classes of dangerous goods that emit hazardous fumes.

🧠 The Human Element: Crew Responsibilities and Continuous Training

Even with advanced technology, the human element remains paramount. Every crew member involved in seafarer cargo operations must be:

Knowledgeable: Thoroughly understand the cargo plan, stability calculations, and specific handling instructions for the cargo onboard.

Competent: Proficient in operating all cargo handling equipment (cranes, derricks, forklifts, lashing gear) safely and efficiently.

Prepared: Always wear appropriate Personal Protective Equipment (PPE), including helmets, safety shoes, gloves, and high-visibility vests.

Drilled: Regularly participate in emergency drills covering fire, spill, cargo shift, and man overboard scenarios relevant to cargo operations.

🌐 Embracing the Future: Digital Tools for Smarter Cargo Handling

The digital revolution has transformed shipping logistics. Modern vessels leverage technology for enhanced cargo handling in shipping:

Cargo Planning Software & Load Calculators: These sophisticated tools allow officers to:

Simulate various loading/unloading sequences to optimize stowage.

Monitor real-time shear forces, bending moments, and vessel stability.

Calculate draft and trim accurately.

Significantly reduce the potential for human error.

IoT Sensors: Increasingly, cargo holds are equipped with sensors to track temperature, humidity, vibration, and even cargo movement, providing immediate alerts for deviations.

Task | Essential Action |

Before Loading | Thoroughly review the cargo plan & loading manual; inspect all cargo gear and securing equipment. |

During Loading | Continuously monitor weight distribution & structural stress; ensure initial cargo securing. |

After Loading | Conduct a final inspection of all lashings; update stability data; prepare for sea. |

During Voyage | Periodically re-check lashings & cargo condition (especially in heavy weather); monitor cargo movement. |

Before Unloading | Coordinate with the port authority & stevedores; adjust ballast to maintain trim & list. |

During Unloading | Maintain symmetrical discharge; monitor stability; ensure clear communication. |

Post-Unloading | Inspect holds for residual cargo/damage; prepare for next cargo. |

📚 Final Thoughts: The Foundation of Every Successful Voyage

Cargo handling and storage are not merely logistical chores; they are a science of balance, precision, and unwavering commitment to safety. For seafarers, mastering these principles is fundamental to ensuring the safety of the ship, the integrity of the cargo, and the well-being of the entire crew.

Remember, whether you're navigating complex port operations or facing the challenges of the open sea, the adage holds true: a well-loaded, properly stowed, and securely lashed ship is a safe and profitable ship. Equip yourself with this knowledge, and contribute to a safer, more efficient maritime industry.

Comments